Adaptability & Multiuse :

MULTANKs are primarily designed to store potable water, due to its exceptional strength and

modular design it can be used as a fire tank at the same time with different outlet levels.

MULTANKs are primarily designed to store potable water, due to its exceptional strength and

modular design it can be used as a fire tank at the same time with different outlet levels.

The tanks have also been successfully deployed as sea water intake tanks, surge tanks, balancing

tanks, grey water storage, retention runway tanks, recycled/ reuse water tanks, irrigation tanks,

rainwater tanks, industrial process water tanks, chilled water storage, warm water storage, etc..

MULTANKs could also be used to certain chemical with additional and/or other optional material

modifications on demand.

MULTANKs are well suited for either outdoor or indoor, and is particularly useful in established

structures with limited access to either supply new storage or to replace older tanks.

Seismic, Snow & Wind Loads:

MULTANKs can be delivered to cover

the most severe specification needs, on

demand to be able to withstand seismic

zone 4, high snow and/or wind load

specifications.

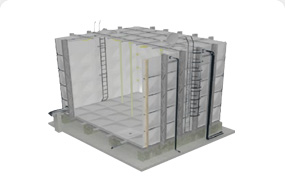

Extendable

Due to the modular nature of our MULTANKs

it can also be extended by adding more

panels in future when more capacity is

required.

Partitions & Baffles:

MULTANKs can also be partitioned or have baffles inside in order to have separate

operating compartments or for water flow characteristics.

Re-locatable:

MULTANKs could be relocated to another location even after years of usage. Simple

un-bolting and re-bolting procedures are required.

Perfect Strength & Durability :

The glass fiber reinforced panels are molded at temperatures up to 150°C using isophthalic

unsaturated polyester resins and are pressed under hot press molding process to realize

optimum condition for maintain the best endurance. The manufacture and the design

of the hot pressed molded GRP sectional storage water tank in comply with the quality

standard of BS EN ISO 9001 and the tank panels have been fully compliant with the

requirements of BS7491:1994:Part 3 / BS EN 13280.

Panel Design & Rigorous Testing:

Computer aided panel design, allied to the immense inherent strength of GRP

material combined with the resilience of a flexible joint system, makes MULTANKs

unmatched in the world for reliability. The tank design has been rigorously tested

and experimented for the worst environmental conditions. Exposed to ensure a reliable

design under all conditions.

No Bacterial Growth:

MULTANKs are hot press molded with perfectly smooth finish, eliminating the problem at

the source. Conventional tanks allow stored water to be in contact with rough surfaces,

this creates a breeding ground for bacterial growth.

Minimal Clearing Requirement:

The smooth interior surfaces, and free-draining design, of the MULTANKs minimizes any

opportunity for pollutants, whether originating internally or externally, to develop and

accumulate. Routine cleaning requirements are consequently simple and infrequent,

with no risk of leaving residual material or cleaning agents inside the tank.

Complete Drainage:

The base of the MULTANK is constructed with convex bottom panels. This not only

provides a positive sealing pressure, which increases as the water height increases, but

also enables a free flow of water from all parts of the tank to the concave drainage panel.

Complete and fast drainage from the lowest point is thus ensured, with no possibility for

static water to accumulate and become stale or contaminated.

Quality Control :

All raw materials used in the manufacture of MULTANKs are agreed to with quality guidelines

and parameters to suppliers. All deliveries are batch tested and crosschecked with

supplier quality data before entering the production environment. Our manufacturing

facility is ISO 9001 certified.

Manufacturing process:

MULTANK panels are hot press molded in glass reinforced plastics (GRP) using isophthalic

unsaturated polyester resins and electrical glass fiber reinforcement.

The panels are moulded at temperatures up to 150°C under strict quality control

disciplines. The process results in strong, consistent panels which are fully cured,

accurate dimension with sharply defined profiles and smooth surfaces on both faces.

Drilling and finishing of the panels is undertaken in a

purpose built controlled area, where high technology

automated drilling equipment is used to complete production to exacting tolerance levels.