We pursue the best system through strict design criteria, quality management, and reliable structural strength analysis.

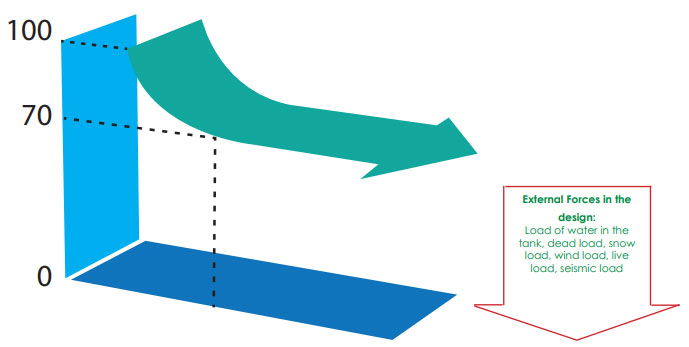

The basic of structure analysis is designed by safety factors against threshold values. We know-how lies in the optimal safety factor in consideration of external force in the design that is expected base on physical properties after long-term use of SMC material.

In designing, the tanks ignores initial value(100%) of the physical properties of SMC material

and considers the safety factor to a minimum value(70%). Therefore, our water tank

guarantees long-term endurance.

| Items | Design Conditions |

|---|---|

| Earthquake | Lateral Seismic Coefficient KH=1/3G |

| intensity of illumination | less than 0.1% |

| Design Conditions | Hydrostatic Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wind Velocity: 60m/sec. 134 mph Snow load: 60kgf/m2 or 12.3 lb/ft2 Man load: 120kgf or 265 lb Seismic load: Horizontal SeismicCoefficient: Kh=0.3 Water temperature 60˚C (max) or 104˚F, this could be increased to 80˚C or 176˚F with special sealant. Anchor bolts shall be used to tie down a tank at the designed points. Note: 1. Panel strength is the actual bursting’ pressure 2. Design can also be made for Kh 2/3, 1.0 and 1.5 |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

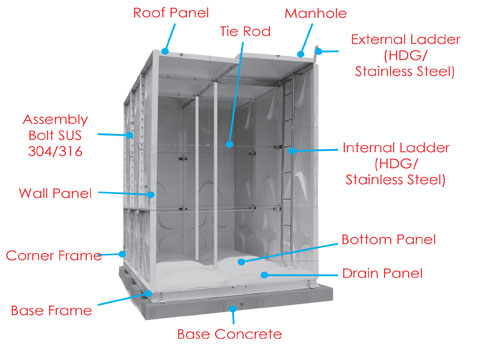

Internal Reinforcement System

The excellent strength, durability and water tightness of the MULTANK are obtained

by connecting inner panels with stainless steel braces & tie-rods are installed inside

of the tank to improve the strength and stability of the tank structure. Corrosionproof

PE heat treated stainless steel tie-rods and GRP tie - rods are applied.

The excellent strength, durability and water tightness of the MULTANK are obtained

by connecting inner panels with stainless steel braces & tie-rods are installed inside

of the tank to improve the strength and stability of the tank structure. Corrosionproof

PE heat treated stainless steel tie-rods and GRP tie - rods are applied.

| 1 | Base Bracket |

| 2 | Anchor Bracket |

| 3 | Base Frame |

| 4 | Air Vent |

| 5 | Corner Frame |

| 6 | Corner Bracket |

| 7 | Cross Plate |

| 8 | Flange Bar |

| 9 | Tie Rod |

| 10 | Roof Stay |

| 11 | Roof Stay Fixer |

| 12 | Ladder |

| 13 | liner |

| 14 | Water Level Guage |

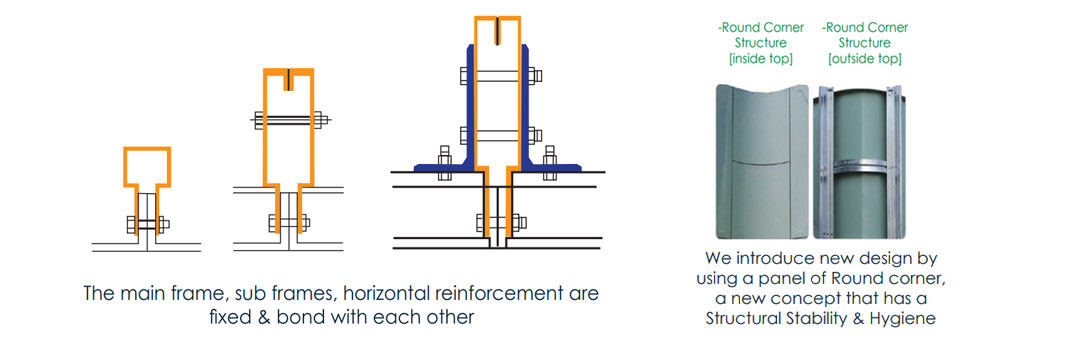

Internal Stay Configuration

1. Materials

2. Inner stay configuration

Minimize the transformation of the side(transformation of 1% or less of the tank height), and it should be so designed as to improve the safety and life of tanks.

| Items | Materials | Specification | Design According |

|---|---|---|---|

| Inner Stay | STS 306 + P.E Coating | Round Bar Ø10.6 (M12 Screw Processing) | BS5950 |

| Internal Bracket | STS 316 Over | 170 X 60 X 5T Over | BS5950 |

External Reinforcement System

MULTANK exterior reinforcement system refers to a system that has been

designed to withstand stress that occurs due to the hydraulic pressure

exerted on the outer part of the tank.

MULTANK exterior reinforcement system refers to a system that has been

designed to withstand stress that occurs due to the hydraulic pressure

exerted on the outer part of the tank.

| 1 | Air Vent |

| 2 | Corner Frame |

| 3 | External Flange Bar |

| 4 | External Bracket |

| 5 | External Ladder |

| 6 | External Frame |

| 7 | Partition Frame |

| 8 | Partition Frame Fixer |

| 9 | Lower Frame Fixer |

| 10 | Roof Stay |

| 11 | Roof Stay Fixer |

| 12 | Partition Frame Fixer |

| 13 | Lower Frame Fixer |

| 14 | Water Level Guage |

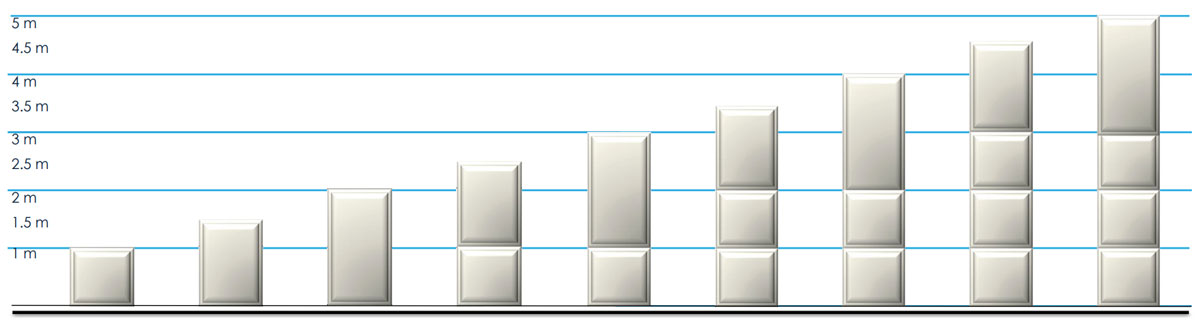

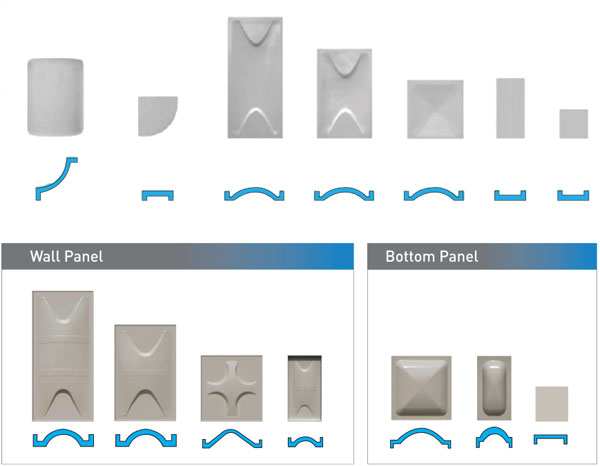

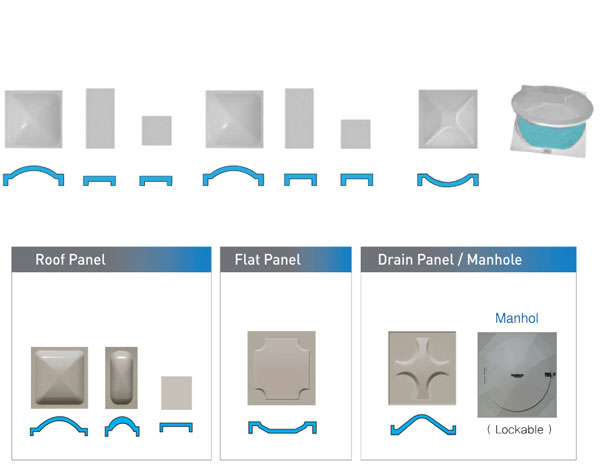

Panel Composition by Height