Polyurethane insulation and cover minimize the water temperature difference and prevent

freezing and condensation.

Polyurethane insulation and cover minimize the water temperature difference and prevent

freezing and condensation.

Insulated panel shall be composed of three layers of SMC panel, Polyurethane (40 Kg/

M3) and SMC Cover or Vacuum formed cover. The thickness of insulation is available at

25mm, 30 mm, 40 mm and 50 mm with water-tightness structure. But, on the part where it is

difficult to assemble the panel, it is possible to use insulation part of below10mm thickness.

(Side Cover: Weather proof treated ASA Material)

Our tank demonstrates outstanding thermal effect and prevent freezing/heating and dew condensation and resistant to Ultraviolet radiation

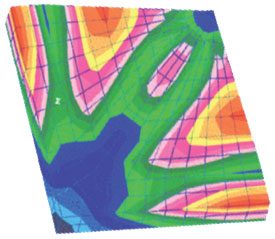

By modeling the radial symmetrical cubic to ¼

sizes, we estimate the strain level of each part when

the load is input. On the part where the stress has

been intensified, we set the load again or increase

the thickness of the panel in order to pursue an

ideal model and develop a high-strength panel

Specification of Optimum design Finite through

Element Method (FEM) using computer and

procurement of reliability through quality

maintenance of designed material property

using intron and hydraulic pressure test.

***Tolerance of dimensions of each panel

shall be within +/-0.03% of the nominal

dimensions. Tolerance regard to panel

and flange angle shall be within +/-0.3%.

**** Panel Strength Tested, giving a factor of safety

in excess of6 times working pressure against rupture.

By modeling the radial symmetrical cubic to ¼

sizes, we estimate the strain level of each part when

the load is input. On the part where the stress has

been intensified, we set the load again or increase

the thickness of the panel in order to pursue an

ideal model and develop a high-strength panel

Specification of Optimum design Finite through

Element Method (FEM) using computer and

procurement of reliability through quality

maintenance of designed material property

using intron and hydraulic pressure test.

***Tolerance of dimensions of each panel

shall be within +/-0.03% of the nominal

dimensions. Tolerance regard to panel

and flange angle shall be within +/-0.3%.

**** Panel Strength Tested, giving a factor of safety

in excess of6 times working pressure against rupture.

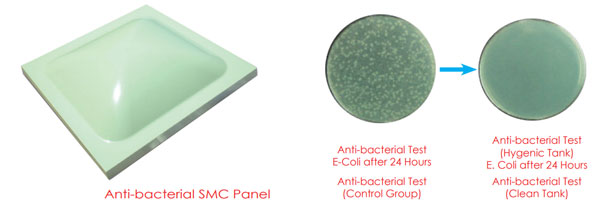

Inorganic Anti-Bacterial agent

Bio-Ceramic

Characteristics of Anti-Bacterial SMC Panel

| Item | Performance Criteria | Anti-Bacterial SMC Panel |

|---|---|---|

| E-Coli | More than 95% | More than 99.2% |

| Staphylococcus Aureus | More than 95% | More than 99.7% |